Many people get on the subway at least once every day and whenever people get to the subway platform, they can see a screen door that slides open and closes along with the train door. Some might think that the platform screen door is not that important, but there are some potential risks behind the thought. The Sungkyun Times (SKT) now explains more about the platform screen door, analyzes the main causes and problems of the Korean screen door system, informs of Korea’s efforts to prevent screen door accidents, and the remaining limitation and venerable examples of Japanese platform screen door system.

Explanation about Platform Screen Doors

Definition of the Platform Screen door

The screen door is a safety device which enables a vehicle to open and close the door, which is connected to the door of the vehicle like a subway train. A screen door is categorized into three types: fixed wall, moveable door, and a door established on the subway platform. In other words, the screen door is a door which blocks the space between the subway track and the platform. The target locations of screen door installations are usually platforms of subways, rapid transit railways, and mono rails. The screen door is opened along with the moveable door of a subway train, when it has completely stopped at a certain platform. Screen doors are divided into three kinds, the completely sealed type, the semi-closed type, and the balustrade type. The completely sealed type thoroughly isolates the track and platform with a high fixed wall. This type of screen door can be seen on Hyehwa station platforms. Secondly, the semi-closed type has an opening device on the fixed wall and a moveable door. This type of screen door reaches half of the whole length of the floor to the ceiling of station. Finally, the balustrade type is a form of balustrade which reaches about as high as an adult’s stomach.

Introduction of Screen Doors

The first screen door was established in the 1960s in Saint- Petersburg, Russia. It was built in the form of iron shutters which moved to the left and right, completely blocking the non-door parts with a marble wall. After its introduction in the United Kingdom, nations such as France, Hong Kong, and Japan also applied screen doors to their subway stations. Korea’s first established screen door in earnest was built on the Gwangju subway line one which was opened in 2004 after the exhibition installation in 2003. The ultimate purpose of the screen door is to decrease noise and dust caused by subway operations, to improve efficiency of the heating and cooling systems of the platforms, and to perfectly prevent citizens from subway safety accidents. Different from this essential purpose, however, screen door accidents in Korea are continuously occurring. There were almost 1200 cases of Korean screen door accidents until last December and fatal accidents have occurred seven times since 2013.

Causes and Problems of Korean Screen Door Accidents Representative Causes of Korean Screen Door Accidents

Frequent Breakdowns Caused by Insufficient Screen Door Management

The number of screen door breakdowns that occurred at 717 subway stations reached 74,238 over the past four years. Cases of screen door malfunctions that occurred from sensor breakdowns are the most frequent among these, which account for 78% of the total number of malfunctions. Sensor breakdowns occurred due to two main reasons. Firstly, sensors in the tunnel often experience detection errors due to dust entering the subway tunnels. Secondly, using refurbished products is also a serious cause. Despite the fact that old equipment causes serious malfunction problems, refurbished products are used because of alternative components’ discontinued production. In addition, poor construction followed by a low bid price for consultancy services also causes serious screen door breakdowns. When a company is selected as the builder of screen doors, it often outsources its construction work to a subcontractor at a very low price. As the subcontractor builds the screen doors with a low budget, the quality of the construction can be poor. This kind of practice continuously leads to poor construction and safety accidents. Although the Korean government declared that change or repair will be implemented to the screen doors with errors on a national scale by 2018, there has been no movement with this plan yet.

Absence of Designated Managers and a Lack of Safety Conscious Operators

In Korea, there are no designated managers who observe and manage the screen door systems and passengers with responsibility. This can be a critical problem in that there is no one who can prevent passengers or workers from screen door accidents. Furthermore, managers’ ignorance toward information about the infrastructure of stations where they work also creates problems. On October 19th, 2016, a 36-year-old man took subway line five to go to work. While he was getting off the subway at Gimpo Airport station, the door of the subway closed and he was trapped between the screen door and the vehicle. He requested the engineer to open the screen door with an emergency call, and soon the door of the subway opened. The screen door, however, did not open and the man could not open the screen door himself. Unlike other stations where the subway door and screen door are opened at the same time, Gimpo Airport station has an old system, which makes the screen doors not open automatically. Finally, he was dragged about seven meters, trapped between the door of the train and the screen door. The subway train stopped through the automatic system, but he died. What is important is the fact that not only the engineer and controller of the station were ignorant of the corresponding station infrastructure, but the safety education manager also had no idea about it. In principle, the engineer and the controller should open the screen door and the subway door manually when an error happens, and should confirm whether passengers get off the subway safely or not. In this case, however, they ignored this and finally were prosecuted for manslaughter.

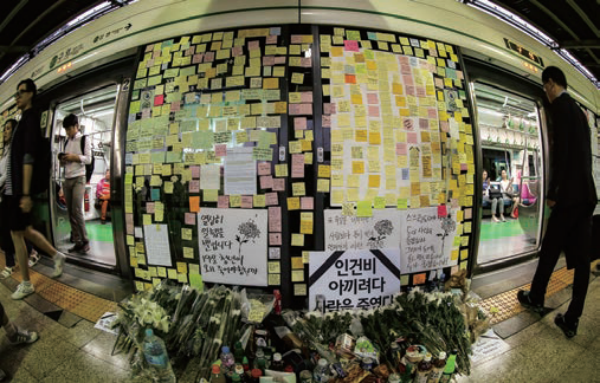

Moreover, a lack of communication among the managers leads to serious accidents. Before repairing the screen door, the manager of the construction company and the manager of the station should communicate about the repair situation. As a result of the absence in communication, a fatal accident occurred again on May 28th, 2016. A mechanic was repairing the screen door malfunction at Guui station on line two. Suddenly, a subway train arrived at the platform without any notice, and the mechanic was trapped between the screen door and the oncoming train. Unfortunately, the mechanic died. If the managers had communicated and gave notice to the mechanic to stop the repair work, this accident would not have happened.

The critical reason as to why these accidents might have happened is the managers’ lack of consciousness toward safety. Among the subway accidents that have occurred in the past five years, the accidents caused by human factors like managers’ violations of safety policies accounts for 37%. Furthermore, the lack of the Korean government’s emphasis on the importance and forcibleness on safety education is also considered as the main factor of screen door accidents.

Absence of Support for Railway Workers’ Safe Operation

There are many problems regarding the treatment of railway workers. Organizations like Seoul Metro and some of the screen door repair companies are not likely to offer the necessary safety devices. Even though they offer the devices, the number of devices is scarce. With a lack of budget, the relevant organizations rarely offer safety devices like helmets and X-bands, which are fluorescent colored safety harnesses that allow engineers and controllers to be seen while working on the railroad. When the Guui station accident occurred, the dead mechanic was not equipped with any safety devices. When an accident occurs, however, the managers attribute not wearing devices as the fault of the individual workers. Furthermore, most companies hardly check whether workers have completed the necessary safety education and wear equipment or not.

Meanwhile, the mechanics work under serious mental pressure. Although companies claim that the guidance of mechanics should move to a malfunctioning screen door within one hour of the breakdown happening, it still occurs. For example, if a malfunction happens at 5:30 pm (after closing hours) and the mechanics arrive at a certain station for repair at 7 pm, then the company enforces workers to submit a report. As workers are decreasing because of the hard work, few workers have to endure a tight schedule. Mechanics work in three groups and work two shifts a day, so they work 15 hours at night for two weeks and work during the daytime for only one week. Additionally, they cannot eat properly since mealtimes are not properly assigned. In the case of the Guui station accident, a cup of ramen was found from the backpack of the mechanic as a meal and many citizens expressed deep regret for it. Furthermore, the weight of the toolbox which the mechanics bring every time weighs approximately 18kg. Mechanics have requested the company installs a toolbox at every station due to the weight of the toolbox. The managers, however, ignored the appeal, and now the mechanics are working in a harsh environment.

Korea’s Effort to Prevent Accidents and Other Country’s Policies

Korea’s Effort and Limitations Remained

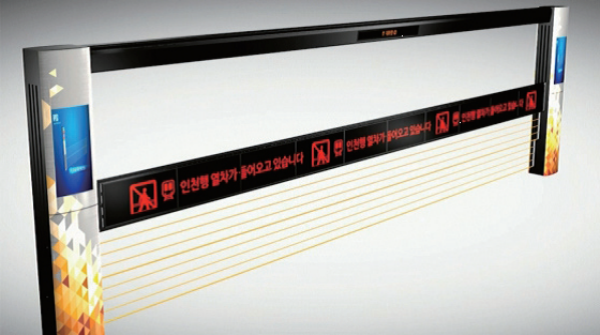

The Ministry of Land, Infrastructure and Transport announced that it will move forward with screen door comprehensive safety measures from February this year. Screen door comprehensive safety measures contain contents for establishing a stronger monitoring system and clarifying the roles and responsibilities of engineers, controllers, and station staff. Additionally, the government promised to change the detection sensors at approximately 300 stations. The most important measure that the government concentrates on is an up and down direction screen door. As accidents occur most with screen doors that move from left and right directions, the government will activate the introduction of an up and down moving screen door. To verify its effect, an exhibition installation has been implemented at Nonsan station in Chungnam province. If the safety of the system is verified, then up and down moving screen doors will gradually be installed on a national scale. The Ministry of Land, Infrastructure and Transport and the Korea Transport Institute expects that the up and down moving screen doors will give more convenience and safety to passengers for the following reasons. Firstly, it will lower passengers’ unreasonable boarding and prevent accidents. Secondly, if the space between screen doors and subway doors becomes more than three times wider, the accidents where passengers are trapped between them should not occur anymore. In contrast, the new system caused chaos because the government does not offer a detailed explanation and accurate statistics. Citizens blamed the government saying that it is like a modern day guillotine and seems riskier than the original system. Although a machine-centered correspondence like changing and repairing the screen door is needed, the consciousness about safety should also be improved.

Screen Door Systems of Japan, How Do They Work?

Japan is the only country that has a screen door system in operation like Korea’s. Screen door accidents, however, are far less common than in Korea. In Japan, there were no accidents caused by screen doors and safety facilities from 2000 to 2016. There are three main policies that they maintain to prevent screen door accidents. Firstly, they persist with a responsible management system. Japan runs screen door systems and safety facilities directly, unlike Korea which allows for subcontracting. Japan never entrusts construction to subcontractors. Secondly, there is a safety staff placement system in Japan. On the Tokyo Yamato line, there is approximately ten safety staff everywhere, people who are composed of part time workers from relevant organizations and employees. Finally, the budget input for citizens’ safety is much more sufficient. Japan uses about ¥611 billion for its safety passenger service, which is 6,656 billion. Conversely, Korea consumes about 100 billion, which is an annual decrease of 20 to 30%. Like this, Korea should also run the screen door system fundamentally concentrated on citizens’ safety, not on the relevant organizations’ benefit.

Although an institutional reform in screen door systems is necessary, passengers’ safety awareness should also be aroused. Citizens will always be awakened to the accidents that can occur. In addition, the government’s effort to advertise and emphasize the importance of safety consciousness education is needed. Efforts by both our citizens and the government will ultimately be the steppingstone for a safer Korea.