In October 2024, the World Bank announced that “1.2 billion people face life-changing risks through exposure to at least one critical climate hazard, such as heatwaves, flooding, hurricanes, and drought,” highlighting the severe climate change worldwide. Since climate change is mainly due to greenhouse gases caused by carbon dioxide, carbon capture and storage (CCS) technology has been in the spotlight. Thus, the Sungkyuntimes (SKT) now delves into the journey of CCS technology to reduce carbon emissions.

Innovative Processes in CCS Technology

-Tracing the Early Days of Carbon Capture

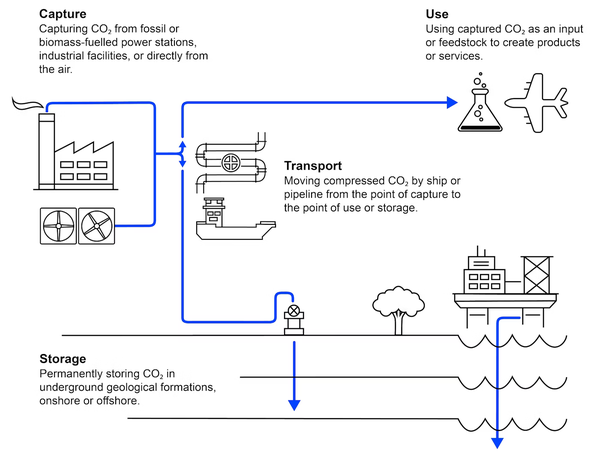

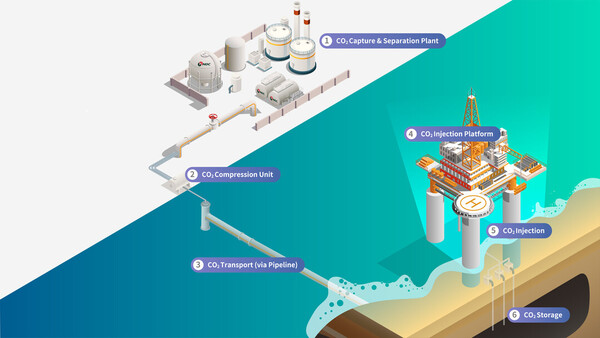

CCS is a three-step process technology that reduces carbon dioxide (CO2) emissions, the main culprits of global warming. It involves capturing CO2 produced by power plants, steel mills, cement plants, and industrial plants, transporting it, and storing it safely underground. The first step, capturing the CO2 for storage, separates CO2 from other gases produced during fossil fuel combustion, accounting for 80% of the total cost of CCS. This capturing technology first appeared more than 100 years ago in the 1930s. It was initially used to remove impurities to obtain high-quality pure gas in natural gas production. The captured CO2 must then be transported to where it can be stored safely, often compressed and transported via pipelines, ships, and trucks. The transported carbon is then stored using two main methods: geological and marine storage. Here, geological storage refers to the injection of CO2 into an appropriate rock formation underground, and marine storage refers to the injection in the deep ocean. CCS, first initiated as carbon capture technology, is now expected to contribute to reducing greenhouse gas emissions, ultimately reaching carbon neutrality goals.

-Tackling Global Emissions for the Future

CCS, commonly used to increase the purity of natural gas and enhance crude oil production, is now recognized as an essential technology for a sustainable future due to the growing awareness of global warming. According to the International Energy Agency (IEA) announcement in 2023, 36.8 billion tons of CO2 were emitted in 2023, accounting for 77% of the planet’s total greenhouse gases, 45% of which were produced by power plants and industries. In this urgent need to reduce carbon emissions, CCS is a crucial technology to address the problem. In 2020, the IEA highlighted the importance of CCS in the 2050 Carbon Neutrality Scenarios, stating, “Without CCS, it is virtually impossible to achieve the goal of limiting global temperature rise to 1.5°C.” Today, oil companies and related companies are leading the CCS business in many countries. This is primarily because the work is similar in nature. Finding an appropriate location to store the CO2 is similar to finding the oil reservoir, and injecting CO2 into storage is similar to the Enhanced Oil Recovery (EOR), commonly used by oil companies. Therefore, the Korea National Oil Corporation (KNOC) is currently taking the lead in Korea. The KNOC is currently in charge of the CCS project, which aims to inject 1.2 million tons of CO2 annually using the Donghae gas field, whose production ended in 2021 as a CO2 storage field. CCS is also a significant issue in various industrial processes, such as steel, cement, and chemical manufacturing.

Navigating CCS Challenges

-Inefficient, Yet Expensive

Although CCS has been receiving worldwide attention, it still faces technological hurdles. Its first stage, the capture process, involves high energy and economic expenditures. Yoon Yeo-il, a principal researcher at the Korea Institute of Energy Research (KIER), shared that a 500MW coalfired power plant that emits 3 million tons of CO2 yearly spends ₩360 billion in the capturing process alone. Such power plants can utilize CCS technology effectively because their higher CO2 emission concentrations make capturing more efficient. Meanwhile, industrial sectors with lower concentration rates may require more energy and costs to achieve the same efficiency level. Beyond this, there are issues that must be tackled in the second CCS phase, where CO2 is transported through a pipeline in a dense liquidlike state. Because this requires a specific temperature and pressure level to be maintained, constructing a pipeline that satisfies these conditions can be expensive. In fact, the United States (U.S.) Department of Energy stated that it will expand a pipeline network of 155,000 km to net zero by 2050. However, the length currently in operation only amounts to 8,050 km due to insufficient funds. These technological and economic issues will further negatively impact the succeeding CCS phases if not addressed.

-A Risky Business

CCS also faces challenges in becoming an economically viable business. The technology entails high initial costs, which makes it difficult for private companies to invest a large amount of capital solely to achieve carbon neutrality. In fact, according to KIER, approximately ₩600 billion is needed to construct the necessary CCS structures for the capturing and liquefaction process. Besides this, revenue models utilizing the captured CO2 are also insufficient, reducing its economic viability. Although Carbon Capture and Utilization (CCU), a technology that transforms the captured highly concentrated CO2 into valuable substances, is being innovated, barriers still exist for private companies to develop it independently. This is because its research and development process takes substantial time and cost. In addition, implementing CCS also means bearing the risk of mid-process interruption because its operating system consists of separate stages. For example, an error in the capture stage could result in halting the transport and storage stages. A lack of standardization across stages necessitates each stage to have different types of equipment and technology, reducing the system’s overall efficiency. These complex problems continue to stand in the way of the active implementation of CCS.

Innovative Solutions for Efficient CCS

-Advancing CCS Technology

There is a significant need for advancements in high-efficiency carbon capture technologies to reduce the high energy consumption and costs associated with the capture phase. In South Korea, KIER is leading the development of CCS technologies, creating an absorbent technology, KIERSOL. KIER Director Yoon Yeoh-il explained to the SKT that KIERSOL directly captures CO2 before the combusted gases exit the chimney — allowing for rapid reaction times, low operating temperatures, and cost-effective, high-efficiency mass capture. This highlights the importance of further research and the urgent need for active commercial CCS-related technologies. A shared pipeline and transport network must also be established to address pipeline challenges. This requires substantial government support due to the high costs and limited resources for private companies to pursue independently. For instance, the U.S. launched a task force in March 2023 to support ongoing CCS projects, including developing CO2 transportation infrastructures such as pipelines. In May 2024, the U.S. Department of Energy’s Office of Fossil Energy and Carbon Management (FECM) announced a $500 million investment to build a safe and reliable CO2 transportation system, expecting to accelerate further CO2 pipeline infrastructure expansion within the U.S. With global collaboration among nations and companies, there is hope for effectively addressing this issue.

-Turning CO2 into Business Opportunities

Developing technologies that actively utilize captured CO2 is essential to create a revenue structure from captured carbon. Glenwood Mason Supply, a U.S.-based construction materials company, uses captured carbon to produce bricks and various construction materials. This company compresses the CO2 collected from residential buildings into a carbon powder similar to dry ice and mixes it with cement, sand, and other materials to make bricks. As such, CCS must advance along with CCU as it enables the chemical transformation of CO2 into fuels or basic chemicals. With advanced CCU, companies could launch businesses using captured CO2, contributing to the revenue structure. Moreover, an integrated CCS system and systematic monitoring should be established to reduce risks related to the independent operation of the capture, transportation, and storage stages. The Ministry of Economy, Trade, and Industry of Japan is leading the Tomakomai CCS Project, which includes a comprehensive monitoring system to detect offshore and onshore activity. Notably, this system successfully detected the tremor during a magnitude 6.6 earthquake in 2019, ensuring no CO2 leakage or injection issues. As such, government-led monitoring systems can enhance safety.

Though there are several mountains to climb, it is vital to embrace CCS technology as an essential component for a greener future rather than simple technical progress. While keeping in mind that today’s challenges become tomorrow’s opportunities, the SKT suggests that Kingos look forward to the further development of CCS technology for a greener environment.